概述

型号

下载

技术信息

相关的

资源

Telecentric light

准直聚焦

核心优势

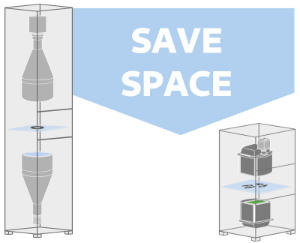

- 在超紧凑结构中实现较大照明面积

LTCLHP CORE PLUS 体积小巧,其长度与市面上其他远心光源相比可缩短 45%。 - 缩小您的视觉系统尺寸

LTCLHP CORE PLUS 远心照明器的工作距离经过优化。 - 提升您测量系统的性能

可以使用 LTCLHP CORE PLUS 照明器来代替平面背光源,以提升系统的性能。 - 智能济的集成方

LTCLHP CORE PLUS 照明器集成了安装法兰,无需额外的夹具即可轻松安装。 - 系统的紧凑性堪称一大竞争优势

小型的视觉系统或测量机器已成为业内首选。

LTCLHP CORE PLUS 远心照明器经过专门设计,可在较小空间内实现大面积照明。该产品的长度与市面上其他远心光源相比可缩短 45%。

远心镜头的长度和工作距离会在很大程度上决定视觉系统的尺寸。此类产品的工作距离范围经过优化,使得测量系统的尺寸尽可能紧凑,从而使系统的整体尺寸缩减了一半之多。

得益于超紧凑的结构,您可在传统远心光源不适用的位置轻松集成 CORE PLUS 准直照明,以代替普通的漫射型背光源,从而提高系统性能。

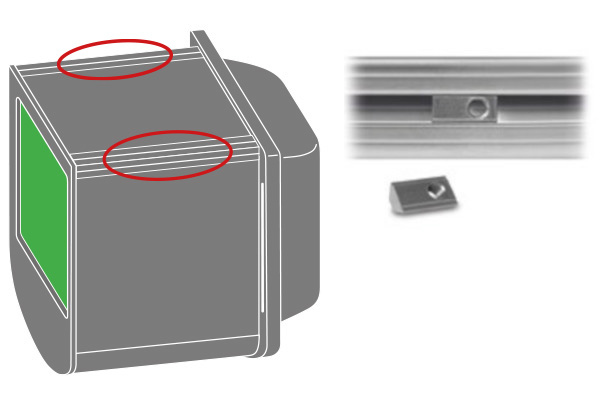

LTCLHP CORE PLUS 光源经过专门设计,实现了智能集成。它们采用了内置安装法兰设计,因此,无需额外的安装夹具便可实现安装。

发现更多

优势

节省更多

• 所用材料更少,制造成本更低• 无需其他夹具固定,从而缩减了安装成本

• 所需存储和使用空间更小

• 尺寸更小,运输费用更低

• 运输风险更低

销量更高

• 系统体积更小,从而推动销售额提升

实际应用案例及案例历史

请稍等

无法处理您的请求

返回型号

过滤器

关闭

重置过滤器

注释

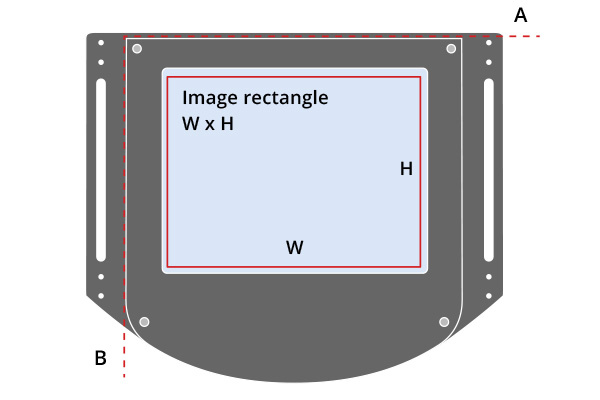

- 光束形状呈非圆形。如需了解最小光束尺寸,请参阅技术信息。

- Opto Engineering®推荐在高精度测量应用中使用绿光。

- 公差± 10%。

- 在最大正向电流下。正向电压测量公差为± 0.06V。

- 在连续(非脉冲)模式下使用。

- 在脉冲宽度<= 10 ms、占空比<= 10%的条件下。必须绕过内置电路板(请参见技术信息)。

- 夹紧法兰的最大尺寸。

- 标称数值,无垫片。

返回型号

参数

Setup instructions 1

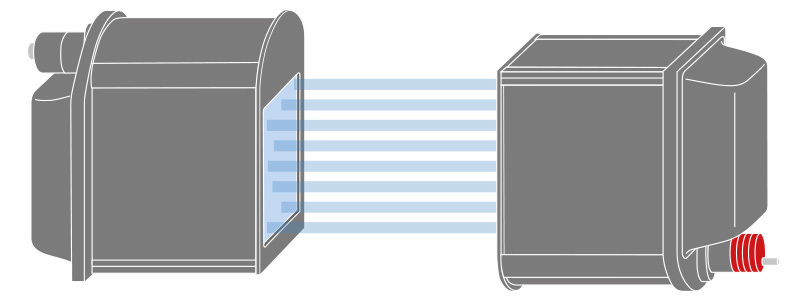

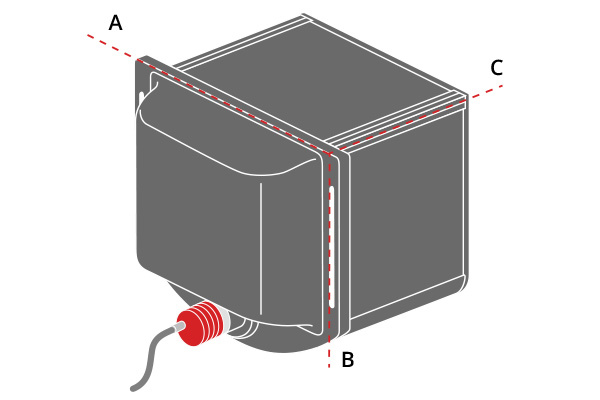

To build a telecentric measurement setup it’s necessary to position a LTCLHP CORE telecentric illuminator upside down with respect to the TC CORE PLUS telecentric lens.

Setup instructions 2

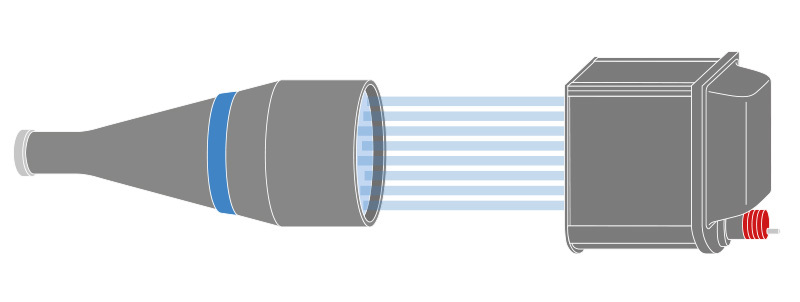

LTCLHP CORE PLUS telecentric illuminator is also a perfect solution when coupled with classic telecentric lenses (e.g. TC series).