新闻

FROM NEEDS TO SOLUTIONS

100% antenna dimensional inspection for the world’s largest radio telescope: Opto Engineering® vision technologies

Need addressed: automating dimensional quality control for high‑volume antenna production, increasing measurement accuracy and repeatability while reducing manual intervention and inspection time.

In large-scale scientific manufacturing, the ability to perform fast, reliable, and fully repeatable dimensional inspections is essential. This need becomes even more critical when thousands of components must meet absolute quality standards for high-precision applications.

To address this challenge, Sirio Antenne implemented a complete vision-based control system to ensure 100% dimensional verification of antennas for the Square Kilometre Array Observatory (SKAO) project. The solution was developed leveraging Opto Engineering® vision technologies, including software, precision optics, cameras, and illuminators. The integrated solution enables accurate and repeatable measurements, reliable inspection workflows, and high throughput quality control, supporting the production of over 78,000 antennas with consistent and verifiable quality.

INSIDE INNOVATION

What have we been working on during the last months of 2025? At Opto Engineering innovation never stops, from cameras to optics, from software to lighting solutions. This ongoing commitment ensures that our customers always benefit from state-of-the-art solutions that meet the highest standards of precision, reliability, and performance in machine vision.

OEVIS 3.0 now features advanced customization options to better address your specific application needs:

🔵 Custom algorithms

- What’s new: Developers can extend OEVIS® by adding proprietary algorithms to the tool library, leveraging .NET and C++ code.

- Interesting for: Developers with .NET and/or C++ programming skills that need custom vision algorithms or to integrate specific hardware (I/O board, third-party framegrabber, …)

🔵 Custom HMI Control Feature

- What’s new: Build even more customized HMIs using .NET 6.0 WPF (Windows Presentation Foundation framework).

- Interesting for: Advanced users looking for full control over UI design and logic (e.g. add custom data tables, plotting controls, or embed external resources in the machine front-end)

🔵 Custom data types

- What’s new: Users can define their own structured data types for advanced customization. This results in improved data consistency and integration with external systems.

- Interesting for: Advanced users that aggregate different data types to consistently transfer information between multiple threads or that group multiple geometric measurements into a single inspection object for easier handling.

🔵 Enhanced C# Scripting

- What’s new: Developers can now access OEVIS® image processing functionalities directly in C# scripts.

- Interesting for: Users with C# development skills.

|

Through focused development efforts, Opto Engineering has built a full range of 12 MP liquid lens optics, designed to deliver high performance and flexibility across multiple applications. Each model can be supplied with a customized

f-number upon request. Below is the full list of available models:

- EL12MP1240: focal length of 12 mm

- EL12MP1640: focal length of 16 mm

- EL12MP2540: focal length of 25 mm

- EL12MP3540: focal length of 35 mm

💡 USEFUL TIPS

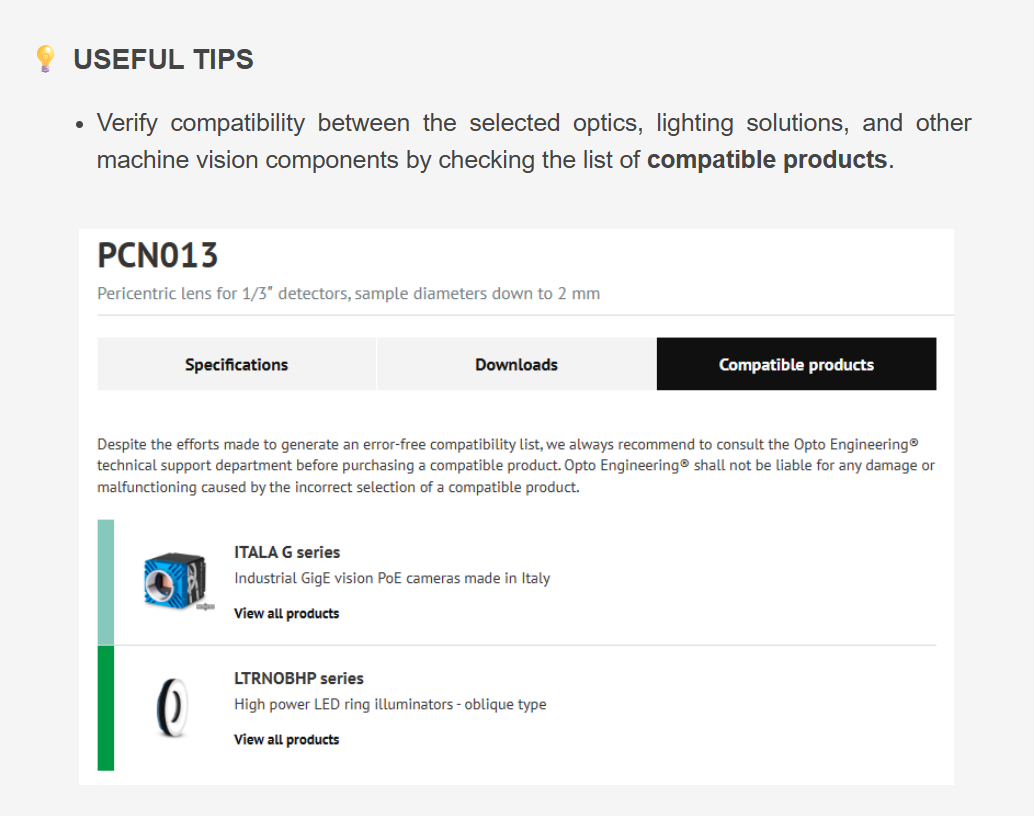

To support enhanced application tuning, we have expanded the available color options: red, white, blue, and green for illuminators from LTRNOBHP series compatible with 360° optics (nano pericentric & hypercentric optics):

- LTRNHP035W45, LTRNHP035R45, LTRNHP035G45 and LTRNHP035B45: compatible with PCN013 (new nano pericentric lens designed for the inspection of small objects with diameters from 2 to 12 mm).

- LTRNHP019W45, LTRNHP019R45, LTRNHP019G45, and LTRNHP019B45: compatible with HCN13010/HCN13040 (hypercentric lens for bottom and side inspection for 1/3" sensors, sample diameters down to 0.75 mm/2 mm).